The material processed by the customer is the raw slurry. The sludge comes from the chemical treatment clarification tank, with a daily sludge production of 2,500 liters, and the solid content fluctuates within the range of 5% to 10%. The customer's regular working hours are 8 to 10 hours per day. During this period, the relevant treatment work of the above-mentioned sludge needs to be completed.

Based on the customer's process requirements, the following configuration was selected after a comprehensive assessment:

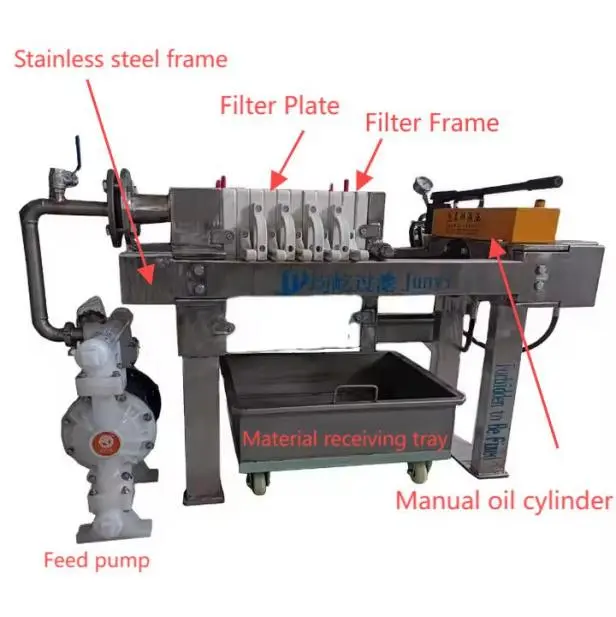

Machine: Plate and frame filter press

Filtration area: 3m³

Filter chamber volume: 38L

Applicable temperature: 45°

Working hours: 8 hours

Core function: Equipped with a manual oil cylinder compression system, the oil cylinder is controlled manually through operation to ensure the sealing of sludge during filtration, dewatering and other processes, effectively preventing sludge leakage.

Key component: Carbon steel receiving tray

This scheme highly meets the customer's demands. The manual cylinder compression system is easy to operate and has low maintenance costs. The carbon steel receiving tray is cost-effective and durable. The overall solution not only meets the processing requirements but also effectively controls the equipment investment and operation costs. Each component of the equipment has a clear division of labor and works closely together. Within the daily working hours of 8 to 10 hours, it can stably complete the daily sludge treatment capacity of 2,500 liters, reduce the risk of failure, and ensure the continuous and efficient operation of sludge treatment work.

Product parameters:

| Basic Parameter | Filtration Area | 3 Square Meters |

| Filter Chamber Volume | 38 Liters | |

| Main Material | Carbon Steel | |

| Feeding Method | Above Feeding | |

| The method of pressing the filter plate tightly | Manual Oil Cylinder | |

| Filter plate | Type | Plate And Frame |

| Material | Reinforced PP | |

| Quantity | 14 Filter Plates +15 Frames | |

| Filter cloth | Model | 750B |

| Accuracy | 200-350 Mesh |

Junyi Copyright © 2025 ALL rights reserved