Product OverviewFully automatic back-washing filter - computer programme control: Automatic filtration, automatic identification of differential pressure, autom

Product Overview

Fully automatic back-washing filter - computer programme control: Automatic filtration, automatic identification of differential pressure, automatic back-washing, automatic discharge, low operating costs.

High efficiency and low energy consumption: large effective filtration area and low back-washing frequency; Small discharge volume and small system

Large filtration area: the machine is equipped with multiple filter elements in the whole space of the tank, making full use of the filtration space. The effective filtration area is generally 3 to 5 times the inlet area, with low back-washing frequency, low resistance loss, and significantly reduced filter size.

Good back-washing effect: Unique filter structure design and cleaning control mode make the back-washing intensity high and cleaning thorough.

Self-cleaning function: the machine uses its own filtered water, self-cleaning cartridge, do not need to remove the cartridge cleaning, and do not need to configure another cleaning system.

Continuous water supply function: There are several filter elements in the tank of this machine working at the same time. When back-washing, each filter element is cleaned one by one, while the other filter elements continue to work, so as to achieve continuous water supply.

Automatic backwash function: The machine monitors the pressure difference between the clear water area and the muddy water area through the differential pressure controller. When the pressure difference reaches the set value, the differential pressure controller outputs a signal, and then the microcomputer electronic control box controls the back-washing mechanism to start and close, realizing automatic back-washing.

High-precision and reliable filtration: The automatic backwashing filter can be equipped with various forms of filter elements according to the solid particle size and PH value of the fluid. Metal powder sintered filter element (pore size 0.5-5UM), stainless steel wire mesh sintered filter element (pore size 5-100UM), stainless steel wedge mesh (pore size 10-500UM), PE polymer sintered filter element (pore size 0.2-10UM).

Operational safety: The machine is designed with a safety protection clutch to protect the machine from overload resistance during backwashing work and to cut off the power in time to protect the mechanism from damage.

Product Details

Product Characteristic

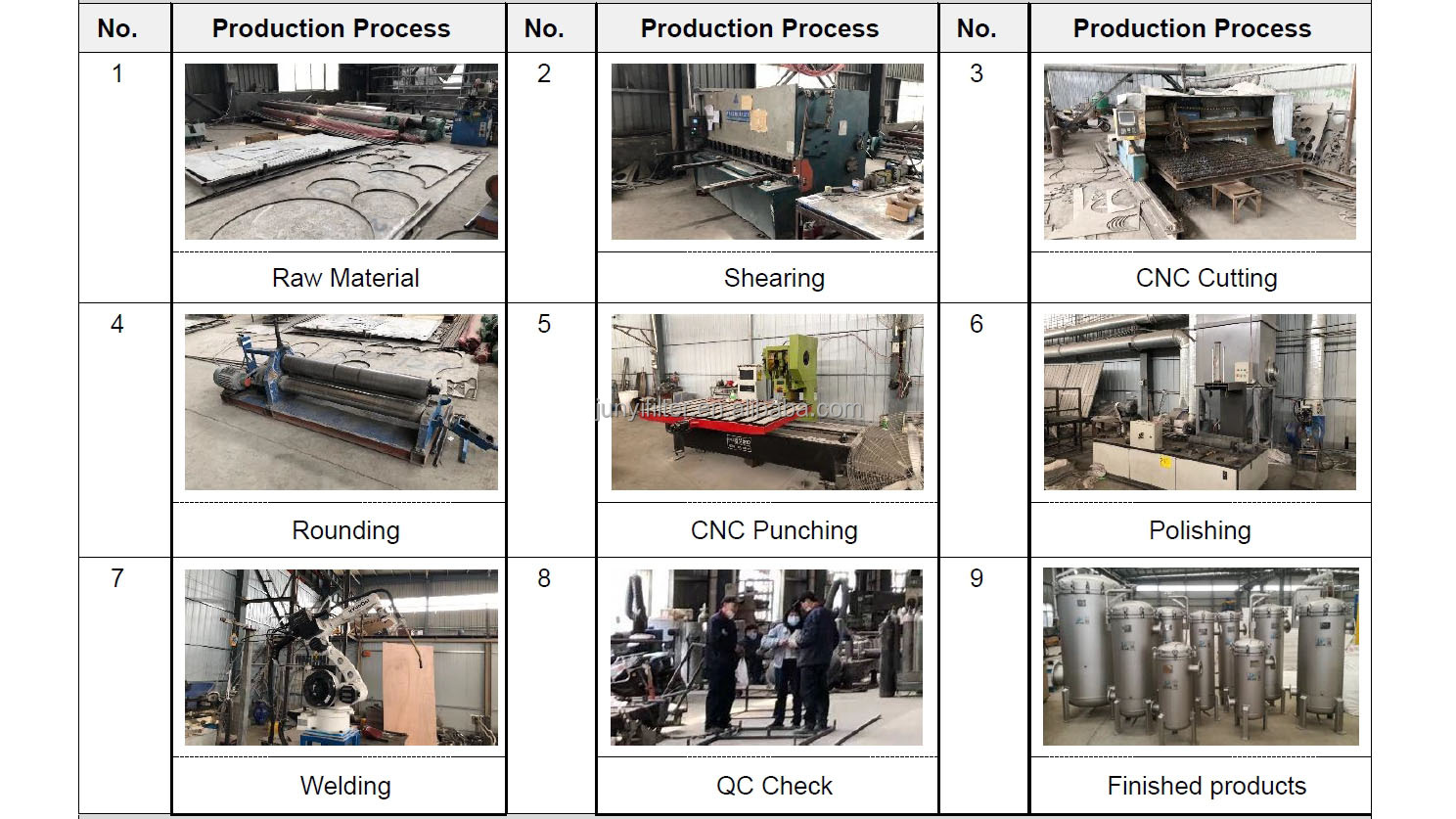

Company Profile

Please feel free to leave a message. We will reply you in 24 hours.

Junyi Copyright © 2025 ALL rights reserved