Product descriptions from the supplierProducts DescriptionMagnetic bar filterMagnetic bar filter is an efficient filter equipment, which mainly uses the magneti

Products Description

Magnetic bar filter

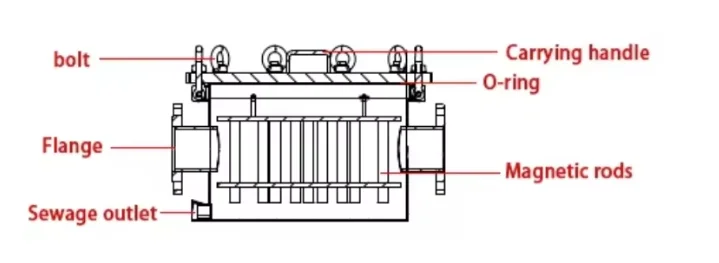

Magnetic bar filter is an efficient filter equipment, which mainly uses the magnetic adsorption capacity of magnetic bars to filter and exclude ferromagnetic impurities in the fluid. Specifically, the working principle of the magnetic bar filter is to insert a number of magnetic bars into the medium, and absorb the ferromagnetic particles in the medium on the surface of the magnetic bar through the magnetic action, so as to achieve the purpose of removing the ferromagnetic impurities in the medium.

The working principle of magnetic bar filter is mainly based on magnetic adsorption. The filter is equipped with one or more sets of strong magnetic rods, which are carefully designed and arranged in the core of the filter. When the fluid containing ferromagnetic impurities (such as liquid or gas) passes through the magnetic bar filter, the ferromagnetic impurities in the fluid (such as iron filings, rust, magnetic particles, etc.) will be attracted by the strong magnetic field of the magnetic bar. These impurities are adsorbed to the surface of the magnetic rod and thus separated from the fluid. As the fluid continues to pass through, more and more ferromagnetic impurities are adsorbed on the magnetic rod, and the fluid gradually becomes clean. This process not only improves the quality of the fluid, but also protects downstream equipment from impurities. The design of the magnetic bar filter allows the magnetic bar to be easily removed for cleaning when needed. Once the impurities on the magnetic rod have accumulated to a certain extent, it is necessary to clean up the operation. When cleaning, it is usually only necessary to remove the magnetic rod from the filter, remove the impurities attached to it, and then return the magnetic rod to the filter. In summary, the magnetic bar filter effectively separates the ferromagnetic impurities in the fluid through the use of magnetic adsorption, so as to achieve the purpose of filtering and purifying the fluid. This filter has the advantages of high efficiency, stability and easy cleaning, and is widely used in many industries.

Product Details

|

Magnetic bar filters have a number of significant features and advantages that make them ideal for filtering ferromagnetic impurities in a variety of industrial applications. The following are the main features and advantages of the magnetic bar filter: |

||||

|

High efficiency iron removal capability |

The magnetic bar filter is made of strong magnetic materials, which can efficiently adsorb ferromagnetic impurities in the fluid, such as iron filings, rust, magnetic particles, etc., thus significantly reducing the iron ion content in the fluid. |

|||

|

Compact structure |

Magnetic bar filters are usually designed to be compact, take up little space, and are easy to install and maintain. This compact design not only saves space, but also improves filtration efficiency. |

|||

|

Easy to clean |

The cleaning process of the magnetic bar filter is relatively simple and fast. When the impurities on the magnetic rod accumulate to a certain extent, just remove the magnetic rod from the filter, clean up the attached impurities, and then reinstall it. This design reduces maintenance time and costs. |

|||

|

Adaptable |

Magnetic bar filters are suitable for a variety of fluid media, including liquids and gases. At the same time, it can also adapt to different temperature, pressure and flow conditions to meet the needs of different industrial applications. |

|||

|

Durable and reliable |

Magnetic bar filters are made of high-quality materials with high wear resistance, corrosion resistance and high temperature resistance. This ensures the long-term stable operation and reliability of the filter under harsh conditions. |

|||

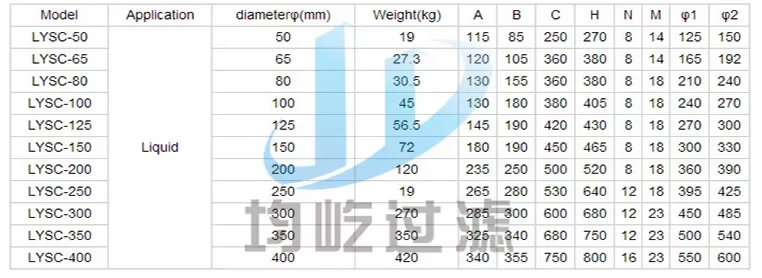

Specification

Company Profile

Shanghai Junyi Filter Equipment Co., Ltd. specializes in the manufacturing and sales of filter equipment. We have professional and experienced technical team, production team and sales team, provide good service before and after sales. Adhering to the modern management mode, we always make the precision manufacturing, explore new opportunity and make the innovation.

After years of hard exploration, we has established a complete and effective service system and built an experienced service team, which not only provides customers with site planning and drawing of the layout and flow chart, but also can send our technical personnel to the site to guide the installation and commission for our customers.

We have a very strict and complete quality control system, which promises that goods we produced are always of the best quality, the enough inspectors to ensure that each product can meet the quality requirements of customers. We always final Inspection before shipment.

We produce more than 200 different models of the filter. The main products are the Press Filter / Bag Filter Housing / Automatic self cleaning filter / Basket filter / Magnetic filter / Candle filter / Leaf filter / Cartridge filter housing / Filter Plate / Filter Cloth/ Filter Cartridge /Filter Bag, also matched tanks, conveyors, etc. These equipment are widely used for the solid-liquid separation process in the industrial of mineral processing, petroleum, chemical industry, dyestuff, metallurgy, food, coal and carbon, inorganic salts, alcohol, light industry, textiles, environmental protection, energy and so on.

Packing & Shipping

FAQ

Q: Are you manufacturer?

A: Yes. We are experienced manufacturer of filter equipment.

Q:What products you provide?

A: We produce more than 200 different models of the filter. The main products are the Press Filter/Bag Filter Housing/Automatic self cleaning filter/Basket filter/Magnetic filter/ Candle filter/Leaf filter/Cartridge filter housing/Filter Plate/Filter Cloth/ Filter Cartridge /Filter Bag, also matched tanks, conveyors, etc.

Q: How to select the type you needed?

A: We will ask you some information: solid liquid kind, usage, flow rate, solid content

percentage, working temperature & pressure, etc. We have professional technical team which will work together with our sales to help you choose the suitable machine for you.

Q.Is it easy to operate for the new user ?

A: Yes. We offer you manual book and operating video. When you have any questions during using, we will answer you within 24 hours. For large projects, we can also send our engineers to your site for commissioning and training.

Q: What's MOQ?

A: 1 PCS.

Q: Do you accept OEM?

A: Yes.

Q:What's the payment terms ?

A: T/T, Western Union, L/C , Alibaba trade order or others. Generally 50% in advance, 50% before shipping.

Q:Quality Warranty.

A:12 months after the installation and commission or 18 months after it has been delivered to the site of the customer.

Please feel free to leave a message. We will reply you in 24 hours.

Junyi Copyright © 2025 ALL rights reserved