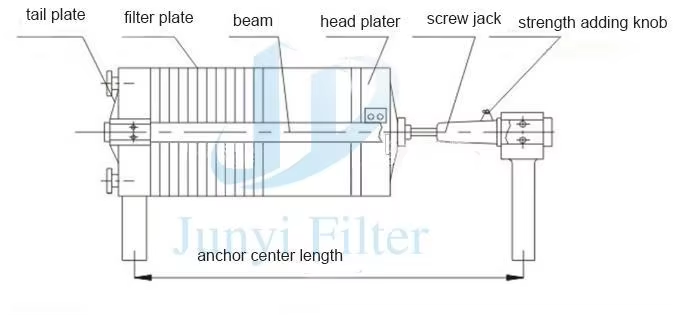

When a jack-driven filter press is in operation, the handwheel is rotated. The small gear and large gear drive the lead screw to push the pressure plate, tightly pressing the filter plates and the filter medium between the pressure plate and the thrust plate. This enables the slurry to be pressurized and filtered in the filter chamber under the working pressure. Under pressure, the liquid passes through the filter cloth and is discharged as filtrate, while the solid particles are intercepted on the filter cloth to form a filter cake. When the filter chamber is filled with the filter cake, the filtration process is completed.

Characteristics

Advantages :It has a simple structure and is easy to operate. It does not require a power supply, making it cost-effective. It is suitable for filter presses with a filtration area ranging from 1 to 40 square meters and is generally used in the filtration fields with low pressure, where the filtration pressure is less than 0.4MPa.

Disadvantages:It has a low degree of automation, relatively low filtration efficiency, a small throughput, and is not suitable for large-scale production and filtration scenarios with high pressure requirements.

Main Components and Materials

Filter Plates

Currently, the filter plate of filter press is made of polymer or polymer coated steel. According to the needs, the filter plate can also choose cast iron or stainless steel materials, which provide a good corrosion resistance, acid and alkali resistance, certain mechanical strength and good drainage surface for the filter cloth. The size range of the filter plate is 250 ×250 mm to 2.0 × 2.0 meters, and larger or smaller sizes are available.

Jacks

The main body of the jack is usually made of high-quality carbon steel or alloy steel, and its piston rod is generally made of high-strength alloy steel and undergoes surface chrome plating treatment. Carbon steel and alloy steel have high strength and toughness and can withstand large pressures. Chrome plating treatment can improve the wear resistance, corrosion resistance, and surface finish of the piston rod, ensuring the stable operation and long service life of the jack.

Frame

The frame is generally welded from section steel such as channel steel and I-steel, and its surface is painted or treated with anti-corrosion measures. Section steel has high strength and rigidity and can withstand various forces during the operation of the filter press, ensuring the stability of the equipment. Painting or anti-corrosion treatment can prevent the frame from being corroded by the external environment and extend the service life of the equipment.

Feeding Device

The feeding pipeline is usually made of stainless steel or corrosion-resistant plastic materials such as polytetrafluoroethylene (PTFE) and polypropylene (PP). Stainless steel has good corrosion resistance and strength and is suitable for the transportation of most chemical materials. Plastic materials such as PTFE and PP have excellent corrosion resistance, wear resistance, and a low coefficient of friction, which can effectively prevent materials from adhering and clogging in the pipeline.

Junyi Copyright © 2025 ALL rights reserved