Product descriptions from the supplierProducts Description Product Name Diatomaceous earth filter/ Kieselguhr filter/ Pre-coat Filter

Products Description

|

Product Name |

Diatomaceous earth filter/ Kieselguhr filter/ Pre-coat Filter |

|

Filter Media |

Diatomaceous earth/ clay/ active carbon |

|

Flow |

500L/H-----5000L/H |

|

Power |

0.75KW-----5.5KW |

|

Filter discs |

15 PCS------33 PCS |

|

Working Pressure |

<0.2Mpa |

|

Main material |

Sanitary 304 Stainless Steel |

|

Water pump |

Self-priming pump / centrifugal pump |

Diatomaceous Earth Filter

Diatomaceous earth filter refers to the coating filter with diatomaceous earth coating as the filtration layer, mainly using the mechanical sieving action to deal with the water filtration treatment process containing tiny suspended matters. Diatomaceous earth filters filtered wines and beverages have unchanged flavour, are non-toxic, free of suspended solids and sediments, and are clear and transparent. The diatomite filter has high filtration accuracy, which can reach 1-2 microns, can filter out Escherichia coli and algae, and the turbidity of the filtered water is 0.5 to 1 degree. The equipment covers a small area, low height of the equipment, the volume is only equivalent to 1/3 of the sand filter, can save most of the investment in civil construction of the machine room; long service life and high corrosion resistance of filter elements.

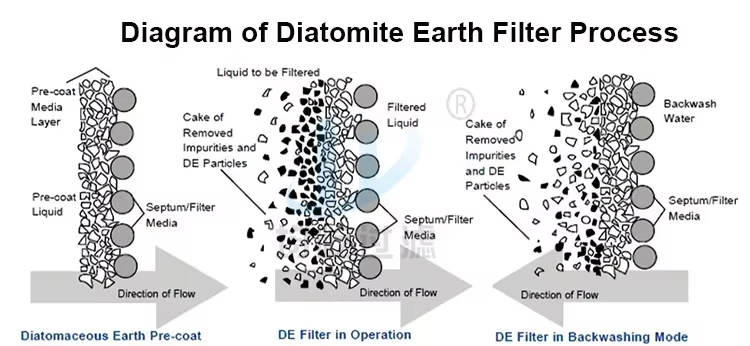

Working Principle

When the Diatomaceous Earth Filter makes the filtration, it will form into the precoating on the filter discs first. When the

liquid to be filtered go through the precoating, the impurities will be blocked and the clean pured filtered liquid will pass from the gaps among the DE to realize the purification function.

After one filtration cycle, the backwashing pump will clean the filter discs to start the next filtration better.

Structure

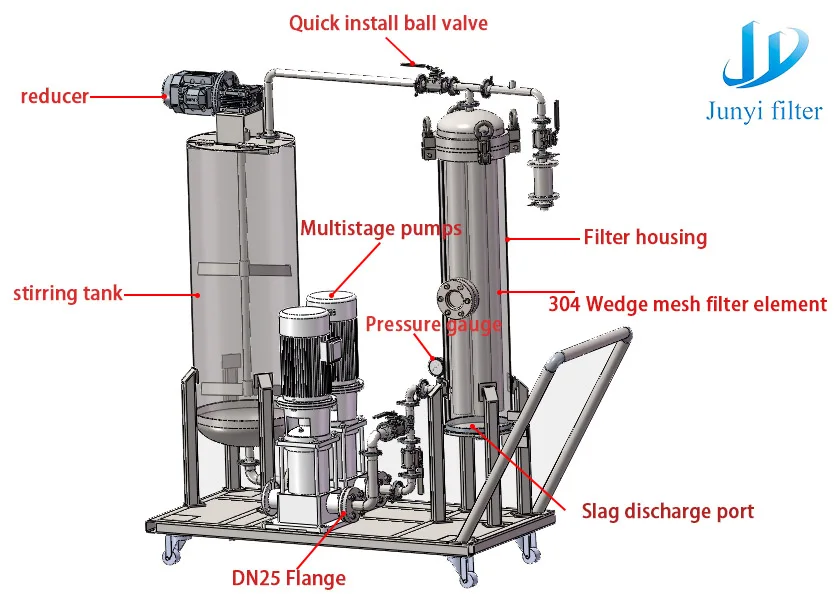

The core part of the diatomite filter is composed of three parts: cylinder, wedge mesh filter element and control system. Each filter element is a perforated tube that serves as a skeleton, with a filament wrapped around the outer surface, which is coated with a diatomaceous earth cover. The filter element is fixed on the partition plate, above and below which are the raw water chamber and the fresh water chamber. The entire filtration cycle is divided into three steps: membrane spreading, filtration and backwashing. The thickness of the filter membrane is generally 2-3mm and the particle size of diatomaceous earth is 1-10μm. After the filtration is finished, backwashing is often done with water or compressed air or both. The advantages of the diatomite filter are good treatment effect, small washing water (less than 1% of the production water), and small footprint (less than 10% of the ordinary sand filter area).

Products Show

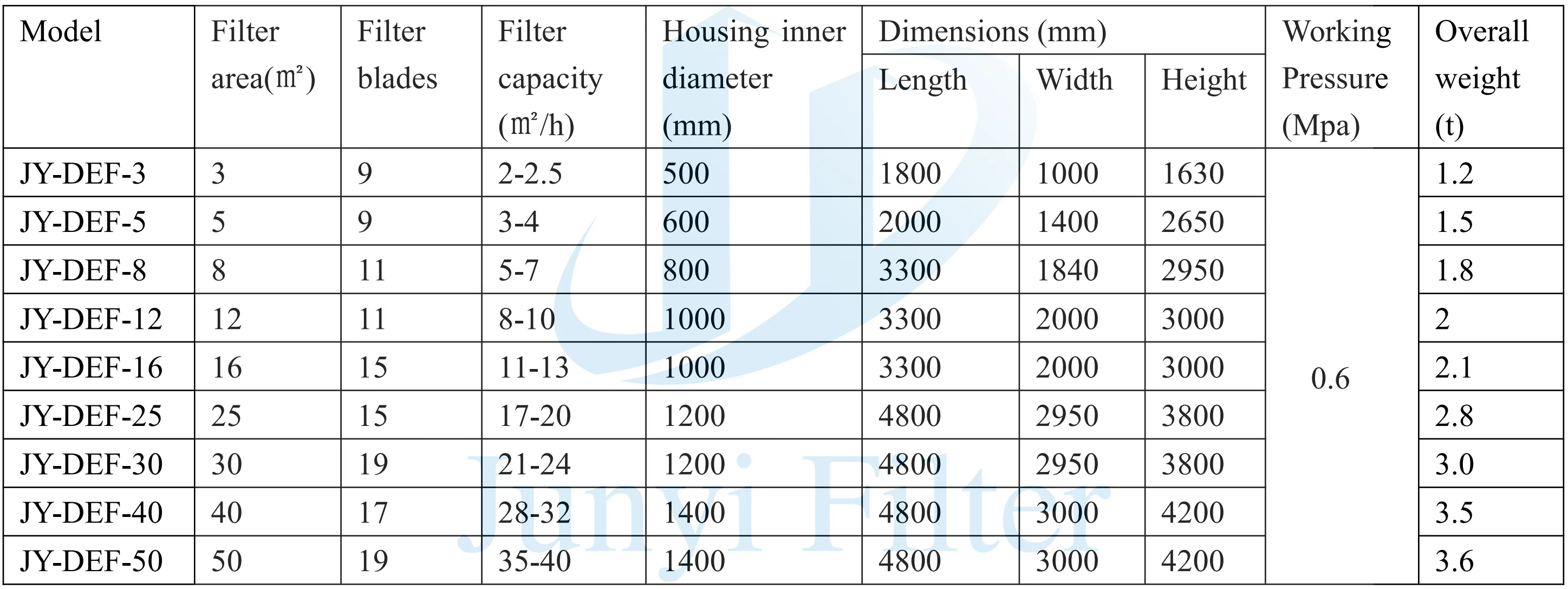

Specification

Company Profile

Shanghai Junyi Filter Equipment Co., Ltd. specializes in the manufacturing and sales of filter equipment. We have professional and experienced technical team, production team and sales team, provide good service before and after sales. Adhering to the modern management mode, we always make the precision manufacturing, explore new opportunity and make the innovation.

After years of hard exploration, we has established a complete and effective service system and built an experienced service team, which not only provides customers with site planning and drawing of the layout and flow chart, but also can send our technical personnel to the site to guide the installation and commission for our customers.

We have a very strict and complete quality control system, which promises that goods we produced are always of the best quality, the enough inspectors to ensure that each product can meet the quality requirements of customers. We always final Inspection before shipment.

We produce more than 200 different models of the filter. The main products are the Press Filter / Bag Filter Housing / Automatic self cleaning filter / Basket filter / Magnetic filter / Candle filter / Leaf filter / Cartridge filter housing / Filter Plate / Filter Cloth/ Filter Cartridge /Filter Bag, also matched tanks, conveyors, etc. These equipment are widely used for the solid-liquid separation process in the industrial of mineral processing, petroleum, chemical industry, dyestuff, metallurgy, food, coal and carbon, inorganic salts, alcohol, light industry, textiles, environmental protection, energy and so on.

Packing & Shipping

FAQ

Q: Are you manufacturer?

A: Yes. We are experienced manufacturer of filter equipment.

Q:What products you provide?

A: We produce more than 200 different models of the filter. The main products are the Press Filter/Bag Filter Housing/Automatic self cleaning filter/Basket filter/Magnetic filter/ Candle filter/Leaf filter/Cartridge filter housing/Filter Plate/Filter Cloth/ Filter Cartridge /Filter Bag, also matched tanks, conveyors, etc.

Q: How to select the type you needed?

A: We will ask you some information: solid liquid kind, usage, flow rate, solid content

percentage, working temperature & pressure, etc. We have professional technical team which will work together with our sales to help you choose the suitable machine for you.

Q.Is it easy to operate for the new user ?

A: Yes. We offer you manual book and operating video. When you have any questions during using, we will answer you within 24 hours. For large projects, we can also send our engineers to your site for commissioning and training.

Q: What's MOQ?

A: 1 PCS.

Q: Do you accept OEM?

A: Yes.

Q:What's the payment terms ?

A: T/T, Western Union, L/C , Alibaba trade order or others. Generally 50% in advance, 50% before shipping.

Q:Quality Warranty.

A:12 months after the installation and commission or 18 months after it has been delivered to the site of the customer.

Please feel free to leave a message. We will reply you in 24 hours.

Junyi Copyright © 2025 ALL rights reserved