Product descriptions from the supplierProducts Description Leaf FilterLeaf Filter (Blade filter) refers to the filter device suitable for the filtration and sep

Products Description

Leaf Filter

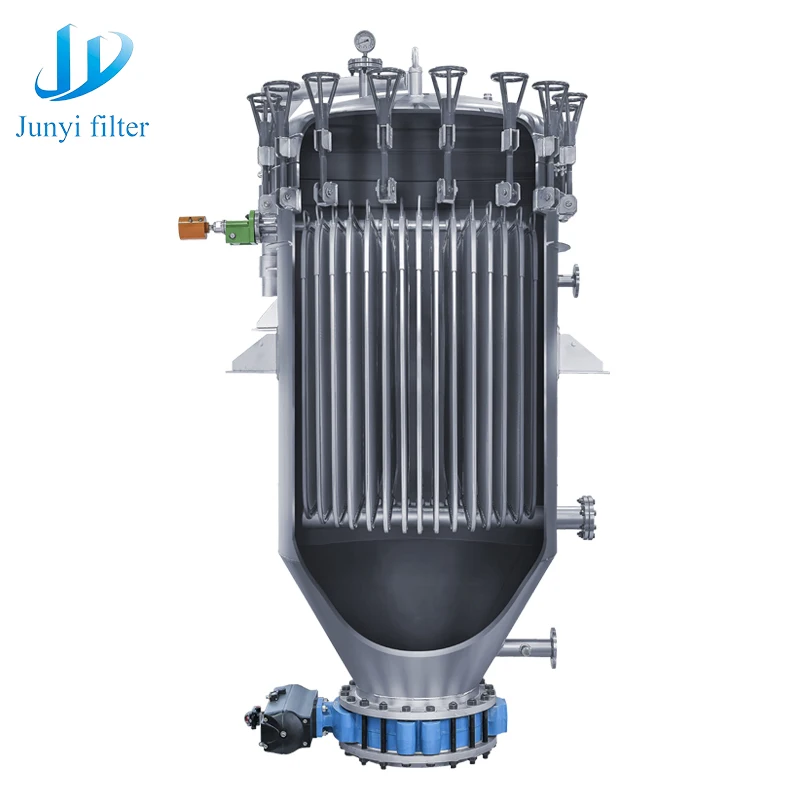

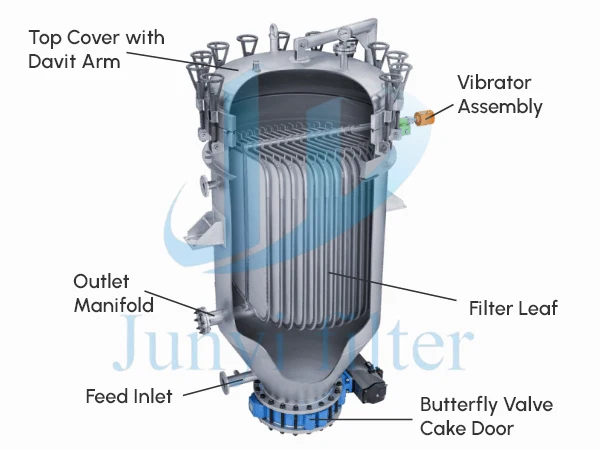

Leaf Filter (Blade filter) refers to the filter device suitable for the filtration and separation process of decolorized oil filtration, clarification filtration and crystal in the production of oil, chemical industry, medicine and other industries. The leaf filter (blade filter) solves the problems of difficult filtration and slag discharge of machine pressed crude oil such as cottonseed, rapeseed and castor in the oil industry.

Structure

Structure

Vertical pressure leaf filter consists of a filter housing, filter leaves, a top cover, a vibrator assembly, a cake discharge nozzle and a manifold. The filter housing is provided with an inlet, an outlet, a davit arm, a butterfly valve, etc. In the filter, filter leaves are evenly placed. At the bottom, filter leaves are inserted into the manifold that collects the filtrate. At the top, filter leaves are clamped by leaf clamping bar with spacer rings to make the filter leave easy to install and remove. The spacing between filter leaves ranges from 30 mm to 100 mm. For wet cake discharge, with or without water spray nozzles are provided.

Products Show

Features

|

Features |

|

1.Reasonable structure,covering less area. |

|

2.Efficient filtration,higher precision,lower loss of material (no need the filter cloth,filter paper or paper element,but only consume the filter aid). |

|

3.Discharging the slag by automatic vibrating.Easy operation and reduce the labor intensity. |

|

4.The mesh is made of stainless steel.No need to be changed.The production can be continuous. |

Specification

|

Temperature :≤ 150 ℃ Working Pressure: Rated Pressure:0.1-0.4 Mpa Max Pressure:0.5 Mpa |

||||||

|

Filtering Area(㎡) |

Filtering Area(㎡) |

Processing Capacity (T/h) |

Volume of Tank |

Weight of Main Part |

||

|

Oil |

Resin |

Drink |

||||

|

2 |

30 |

0.4-0.6 |

1-1.5 |

1-3 |

120 |

300 |

|

4 |

60 |

0.5-1.2 |

2-3 |

2-5 |

250 |

400 |

|

7 |

105 |

1-1.8 |

3-6 |

3-6 |

420 |

600 |

|

10 |

150 |

1.6-3 |

5-8 |

5-8 |

800 |

900 |

|

12 |

240 |

2-4 |

6-9 |

6-9 |

1000 |

1100 |

|

15 |

300 |

3-5 |

7-12 |

8-11 |

1300 |

1300 |

|

20 |

400 |

4-6 |

9-15 |

12-17 |

1680 |

1700 |

|

25 |

500 |

5-7 |

12-19 |

16-21 |

1900 |

2000 |

|

30 |

600 |

6-8 |

14-23 |

19-25 |

2300 |

2500 |

|

36 |

720 |

7-9 |

16-27 |

23-30 |

2650 |

3000 |

|

40 |

800 |

8-11 |

21-34 |

30-38 |

3000 |

3300 |

|

45 |

900 |

9-13 |

24-39 |

36-44 |

3200 |

3500 |

|

52 |

1040 |

10-15 |

27-45 |

42-51 |

3800 |

4000 |

|

60 |

1200 |

11-17 |

30-52 |

48-60 |

4500 |

4500 |

|

70 |

1400 |

12-19 |

36-60 |

56-78 |

5800 |

5500 |

|

80 |

1600 |

13-21 |

40-68 |

64-78 |

7200 |

6000 |

|

90 |

1800 |

14-23 |

43-72 |

68-82 |

7700 |

6500 |

Company Profile

Shanghai Junyi Filter Equipment Co., Ltd. specializes in the manufacturing and sales of filter equipment. We have professional and experienced technical team, production team and sales team, provide good service before and after sales. Adhering to the modern management mode, we always make the precision manufacturing, explore new opportunity and make the innovation.

After years of hard exploration, we has established a complete and effective service system and built an experienced service team, which not only provides customers with site planning and drawing of the layout and flow chart, but also can send our technical personnel to the site to guide the installation and commission for our customers.

We have a very strict and complete quality control system, which promises that goods we produced are always of the best quality, the enough inspectors to ensure that each product can meet the quality requirements of customers. We always final Inspection before shipment.

We produce more than 200 different models of the filter. The main products are the Press Filter / Bag Filter Housing / Automatic self cleaning filter / Basket filter / Magnetic filter / Candle filter / Leaf filter / Cartridge filter housing / Filter Plate / Filter Cloth/ Filter Cartridge /Filter Bag, also matched tanks, conveyors, etc. These equipment are widely used for the solid-liquid separation process in the industrial of mineral processing, petroleum, chemical industry, dyestuff, metallurgy, food, coal and carbon, inorganic salts, alcohol, light industry, textiles, environmental protection, energy and so on.

Packing & Shipping

FAQ

Q: Are you manufacturer?

A: Yes. We are experienced manufacturer of filter equipment.

Q:What products you provide?

A: We produce more than 200 different models of the filter. The main products are the Press Filter/Bag Filter Housing/Automatic self cleaning filter/Basket filter/Magnetic filter/ Candle filter/Leaf filter/Cartridge filter housing/Filter Plate/Filter Cloth/ Filter Cartridge /Filter Bag, also matched tanks, conveyors, etc.

Q: How to select the type you needed?

A: We will ask you some information: solid liquid kind, usage, flow rate, solid content

percentage, working temperature & pressure, etc. We have professional technical team which will work together with our sales to help you choose the suitable machine for you.

Q.Is it easy to operate for the new user ?

A: Yes. We offer you manual book and operating video. When you have any questions during using, we will answer you within 24 hours. For large projects, we can also send our engineers to your site for commissioning and training.

Q: What's MOQ?

A: 1 PCS.

Q: Do you accept OEM?

A: Yes.

Q:What's the payment terms ?

A: T/T, Western Union, L/C , Alibaba trade order or others. Generally 50% in advance, 50% before shipping.

Q:Quality Warranty.

A:12 months after the installation and commission or 18 months after it has been delivered to the site of the customer.

Please feel free to leave a message. We will reply you in 24 hours.

Junyi Copyright © 2025 ALL rights reserved