Product descriptions from the supplierProducts DescriptionStainless steel filter pressStainless steel filter press, also known as stainless steel plate and fram

Products Description

Stainless steel filter press

Stainless steel filter press, also known as stainless steel plate and frame filter press, is a kind of equipment widely used in the field of industrial filtration. It is made of 304/316 high-quality stainless steel material, with corrosion resistance, durable characteristics. The device applies pressure to make the liquid flow out through the filter cloth or filter membrane, and the solid particles are trapped on the filter medium, so as to achieve the purpose of solid-liquid separation.

The working principle of stainless steel filter press is mainly based on the combination of pressure and filter cloth (or filter membrane). During the filtration process, the suspension is pumped into each closed filter chamber of the filter press. Under the action of working pressure, the filtrate passes through the filter membrane or other filter materials and is discharged through the outlet; The filter residue remains in the frame to form a filter cake. In this way, the stainless steel filter press can effectively achieve solid-liquid separation.

Product Details

|

The main function of the diaphragm filter press is to realize the solid-liquid separation process efficiently and accurately.Specifically, its main role includes the following aspects: |

||||

|

Excellent material |

The whole machine is made of 304/316 high-quality stainless steel material, which has excellent corrosion resistance and can adapt to various acid and alkali environments to ensure long-term stable operation of the equipment. |

|||

|

Flexible structure |

The filter plate/filter frame design is flexible, and different filter materials can be replaced according to different material characteristics and filtration requirements (such as microporous filter membrane, filter paper, filter cloth, etc.). At the same time, the equipment can be selected according to customer on-site requirements of open or closed structure. |

|||

|

Good filtration effect |

Equipped with high-efficiency filtration elements such as microporous filtration membranes, to ensure that the filtration effect meets the design requirements, to solve the filtration problems in chemical, pharmaceutical, food and other industries. |

|||

|

A multi-purpose machine |

With two stage filtration function, a liquid can be entered to achieve the initial liquid semi-fine filtration and fine filtration and other filtration modes to meet different process needs. |

|||

|

Easy operation |

The equipment is simple and convenient to operate, and the maintenance cost is low. Before use, it is necessary to carry out preparation work such as disinfection of injection water and wetting of filter material; In the shutdown, it is necessary to close the inlet brake and then shut down to prevent the liquid backflow from damaging the filter material. |

|||

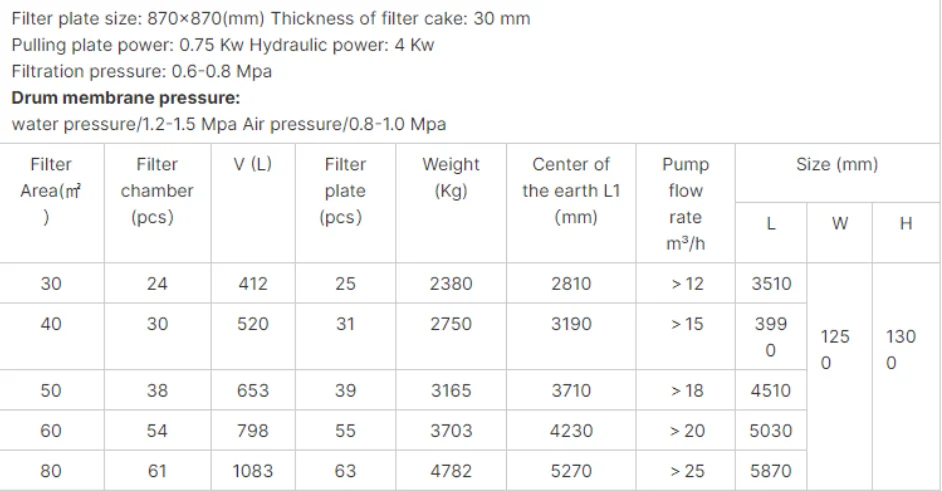

Specification

Company Profile

Shanghai Junyi Filter Equipment Co., Ltd. specializes in the manufacturing and sales of filter equipment. We have professional and experienced technical team, production team and sales team, provide good service before and after sales. Adhering to the modern management mode, we always make the precision manufacturing, explore new opportunity and make the innovation.

After years of hard exploration, we has established a complete and effective service system and built an experienced service team, which not only provides customers with site planning and drawing of the layout and flow chart, but also can send our technical personnel to the site to guide the installation and commission for our customers.

We have a very strict and complete quality control system, which promises that goods we produced are always of the best quality, the enough inspectors to ensure that each product can meet the quality requirements of customers. We always final Inspection before shipment.

Please feel free to leave a message. We will reply you in 24 hours.

Junyi Copyright © 2025 ALL rights reserved